WEST LAFAYETTE, Ind. — Purdue Applied Research Institute (PARI) and Purdue University experts will study and assess how a vehicle performs in harsh hypersonic environments for the Air Force Office of Scientific Research under a three-year, $1.2 million contract, PARI announced.

This innovative research seeks to improve predictions of vehicle behavior in flight, said Greg Scofield, director of the PARI Hypersonics Lab at the Purdue Hypersonics and Applied Research Facility.

“To me, this is an exciting multidisciplinary opportunity to explore fundamental questions surrounding hypersonic flight with state-of-the-art diagnostic techniques and interrogate boundary layer behavior of hypersonic vehicles,” Scofield said.

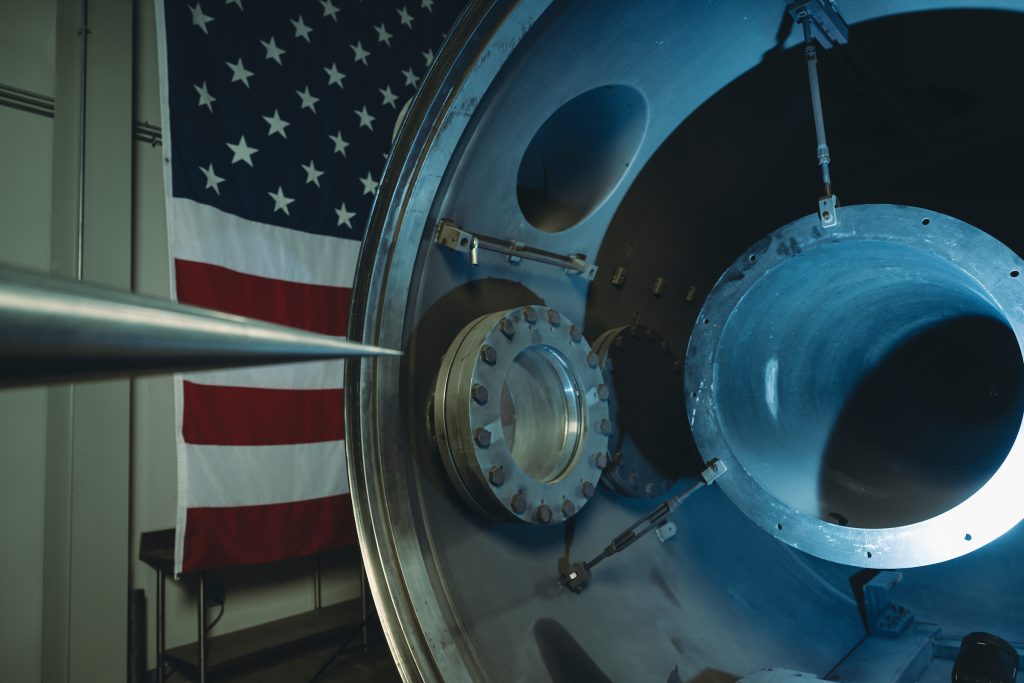

The work, which started this month, will take a multidisciplinary approach using state-of-the-art manufacturing and testing capabilities within the facility, he said. These include the Hypersonics Advanced Manufacturing Technology Center (HAMTC) and HYPULSE reflected shock/expansion tunnel. Scofield and Joseph Jewell, the John Bogdanoff Associate Professor of Aeronautics and Astronautics in Purdue’s College of Engineering and HYPULSE director, are principal investigators on this effort. Program manager is Brett Pokines, who leads the basic research investment in the Agile Science of Test and Evaluation program at the Air Force Office of Scientific Research.

Jewell said he’s especially excited by this effort as it builds on some previous work he did studying outgassing effects on hypersonic boundary layers, going all the way back to work for his PhD.

“We have the opportunity to look for some of the same effects we’ve seen more recently under low-enthalpy, low-disturbance flow in the Boeing/AFOSR Mach 6 Quiet Tunnel,” Jewell said, “with the added aspect of directly creating the elevated gas temperatures that are present in real hypersonic flight. Once high-temperature gas chemistry comes into play, things get very interesting.”

The contract also is an instrument to create security-cleared personnel with profound knowledge for the Air Force test and evaluation community. The research will include about 15 Purdue undergraduate and graduate students, including some who are in partnership with the Air Force Research Laboratory’s Regional Hub at Purdue. Many of the graduate students are military officers studying at Purdue through the Purdue Military Research Institute.

“PARI wants to give the Air Force revolutionary advances in hypersonic capabilities as well as a pipeline for cleared talent,” said Mark Lewis, PARI’s president and CEO. “Developing the workforce needed to maintain and advance these capabilities is at the heart of the PARI mission, not to mention I can’t wait to see the results of our proposed experiments.”

Under the contract, models of hypersonic vehicle components — nosecones, leading edges and other parts of a vehicle — made at HAMTC using additive manufacturing, or 3D printing, will experience simulated high-speed, high-enthalpy environments of the kind that occur in flight, using the HYPULSE tunnel.

The tests will examine certain physical effects present in hypersonic flight. Among them: ablation, an outgassing effect that cools and protects mechanical parts (while progressively removing material) from the extremely high temperatures a vehicle encounters flying through the atmosphere at hypersonic speed; also, boundary layers, which are the thin layer of air in contact with the surface of a craft traveling at hypersonic speed. This airflow creates significant changes in friction-based heating of the vehicle and can affect a vehicle’s aerodynamics.

HYPULSE, which began operating in 2024, coupled with advanced laser diagnostics can simulate and probe the thermodynamic and chemical processes that happen during hypersonic flight using vehicle models produced in HAMTC, Scofield said.

“For the first time, we can use new technology, especially some high-end diagnostic technology, to take those measurements at HYPULSE,” he said. “This will let us measure how we can actively manipulate the boundary layer using gas injection to simulate ablation or transpiration cooling. Understanding these gas interactions will inform the way we model flight behavior, enabling better prediction of vehicle performance and survivability in a given mission.

“Informing our models used for simulating boundary layer and ablation physics of hypersonic flight through ground-based testing is critical to getting the most performance out of a given geometry,” Scofield said. “Ultimately this research is about enabling our designers and engineers to deliver vehicles that can fly faster and farther and more aggressive missions through application of a deeper physics-based understanding of the vehicle behavior.”

About PARI

The Purdue Applied Research Institute (PARI) is a nonprofit entity that extends the reach and impact of Purdue University’s deep research strengths and top-ranked academic programs in engineering, agriculture, science and technology. PARI works to improve national security, global development, infrastructure solutions and to accelerate critical technologies.

Through applied research and program personnel, state-of-the-art facilities and infrastructure, PARI enhances Purdue’s ability to translate discoveries into innovative solutions and services for mission-oriented government, industry, NGO and foundation partners. PARI is an incubator for advanced development and transition of leading ideas and technology with potential for significant impact through large-scale prototypes, pilots and startups. https://pari.purdue.edu/

About Purdue University

Purdue University is a public research university leading with excellence at scale. Ranked among top 10 public universities in the United States, Purdue discovers, disseminates and deploys knowledge with a quality and at a scale second to none. More than 107,000 students study at Purdue across multiple campuses, locations and modalities, including more than 58,000 at our main campus in West Lafayette and Indianapolis. Committed to affordability and accessibility, Purdue’s main campus has frozen tuition 13 years in a row. See how Purdue never stops in the persistent pursuit of the next giant leap — including its comprehensive urban expansion, the Mitch Daniels School of Business, Purdue Computes and the One Health initiative — at https://www.purdue.edu/president/strategic-initiatives.

Sources:

Mark Lewis marklewis@purdue.edu

Joe Jewell jsjewell@purdue.edu

Greg Scofield gscofiel@purdue.edu

Writer/Media Contact: Evamarie Socha ecsocha@purdue.edu